Large Food Processing Plant, NE

RP Constructors quickly expedites wastewater lift station updates for NE food manufacturer, and offers real pricing.

The Client

When a food manufacturer in Nebraska needed a new, innovative solution to handle wastewater, RP Constructors and its sister company, CEC, quickly stepped in to solve the issue, limiting disruptions to production. The client had two issues, a wastewater lift station that wasn’t functioning properly, and an unexpected need to quickly change their biosolids dewatering method. RP Constructors and CEC were hired to design and build solutions for both issues

What We Did

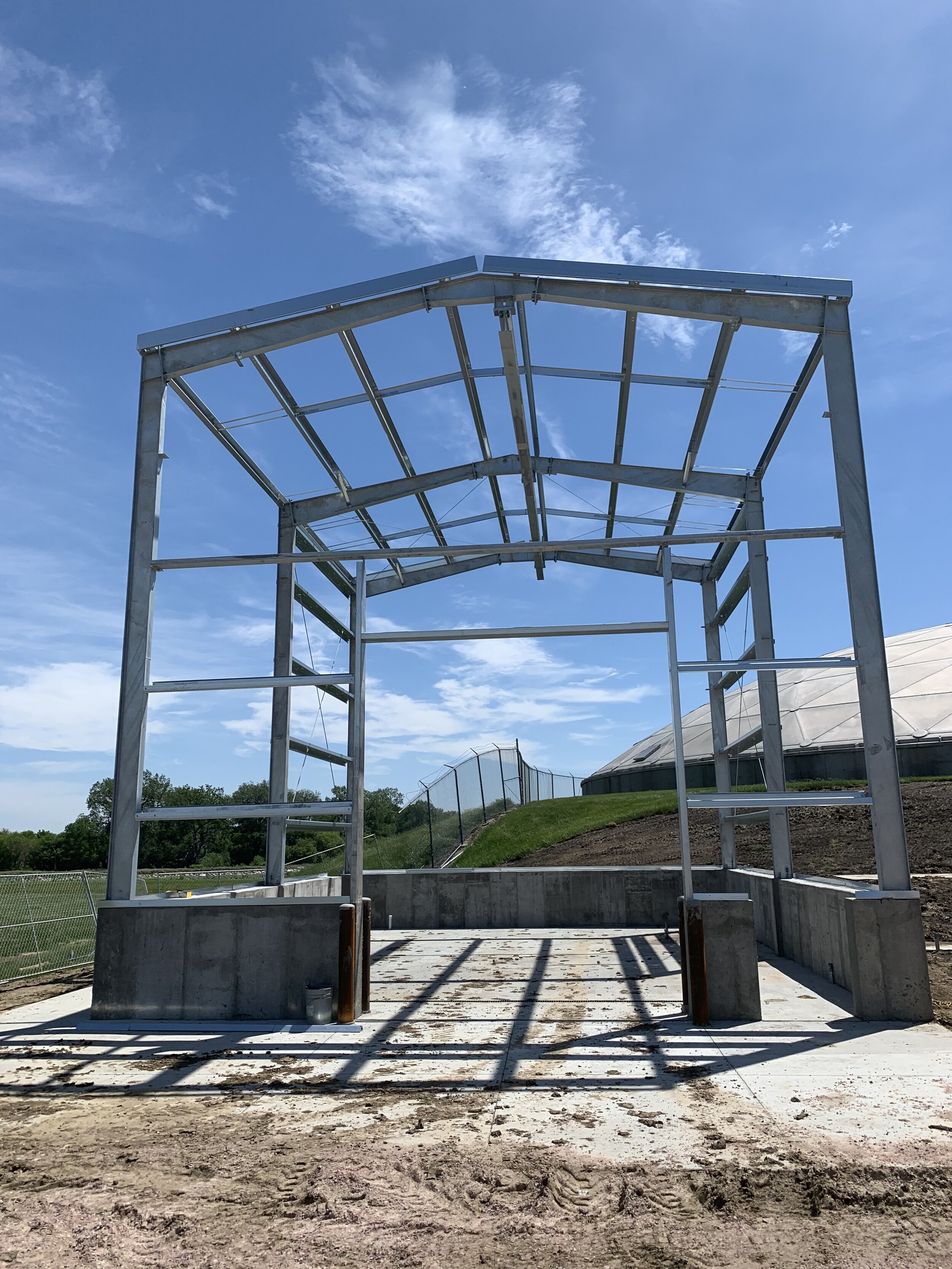

RP Constructors and CEC were hired to design and build solutions for both issues. The first issue centered around a failing wastewater lift station. CEC helped design a new separate wet well/valve vault that better meet the company’s waste needs, and RP Constructors built the system. This wastewater lift station is an integral part of the entire wastewater system. If it goes down, the entire plant goes down. A new lift station was built in parallel to the old, and service was transferred to the new system.

For the second problem, the company needed help dewatering their biosolids. Biosolids are the solids left over after the wastewater treatment process, and if properly treated, can be viewed more as a commodity than an expense The plant had a year to fix the problem, and RP Constructors and CEC found a solution and met the deadline.

CEC drafted conceptual plans at no cost to the client, and. RP Constructors took the plan, priced a firm bid that in turn got the project approved by company leadership.

RP Constructors and CEC were able to provide fair numbers as to what the project would cost to complete at the initial, conceptual design/budgeting stage. Because we have experience in both design and build aspects of wastewater systems, we were able to give them accurate bids instead of a conceptual estimate—this was used by the client to sell the projects to their corporate leadership. Much of our initial, conceptual design and budgeting was completed at no cost to the client.

Services Provided

Land surveying, topographic surveying, environmental and structural Civil Engineering.

Dirt work, underground piping, and heavy civil engineering.

Our Industrial division installed equipment and process piping

As both engineers and contractors, we were able to see what was critical for the plant and expedite the projects efficiently; there are no communication gaps between our two companies. Our estimates were accurate, and less than other contractors would price given so much of the work was self-performed internally by the companies.